|

Multilin M60

Motor Protection System

The M60 motor protection system offers comprehensive protection and control solutions for medium to large-sized three-phase motors. The M60 provides superior protection, control, and diagnostics that include thermal model with RTD and current unbalance biasing, stator differential, reverse and low forward power, external RRTD module, two-speed motors, reduced voltage starting, broken rotor bar detection, and more. Key Benefits

Applications

|

|

New and Enhanced Communication Capabilities

|

|

Cyber Security - CyberSentry UR (FW v7.xx) CyberSentry enables UR devices to deliver full cyber security features that help customers to comply with NERC CIP and NITIR 7628 cyber security requirements through supporting the following core features:

|

|

Fully Compatible with GE's Multlilin HardFiber System - Provides support for GE's IEC 61850 HardFiber Process Bus Solution:

|

|

Extended Oscillography Records

|

|

Broken Rotor Bar Detection - Eliminate costly downtime with intuitive analysis and detection of broken rotor bar conditions.

|

Remote RTD (RRTD) Module - Enables Monitoring of Remote RTDs

|

|

New and Enhanced Protection and Control Functionality

|

Key Features

Protection & Control

The M60 motor protection system offers comprehensive protection and control solutions for medium to large-sized three-phase motors. The M60 includes advanced automation and communication capabilities, extensive I/O options, and powerful fault recording features that can simplify postmortem fault analysis and help minimize motor downtime. As part of the UR Family, the M60 provides superior protection and control.

Functional Block Diagram

ANSI® Device Numbers & Functions

|

|

|

Key Features

Monitoring & Diagnostics

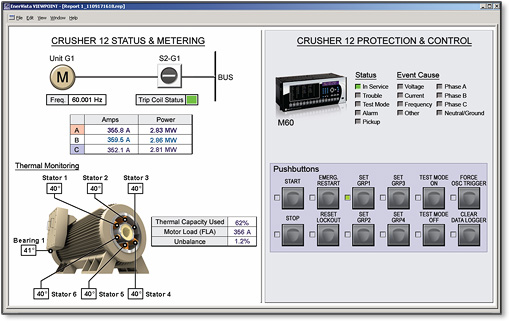

The M60 provides protection, control, metering, and monitoring in a single device, easily integrated into existing HMI or SCADA monitoring and control systems

Advanced Automation

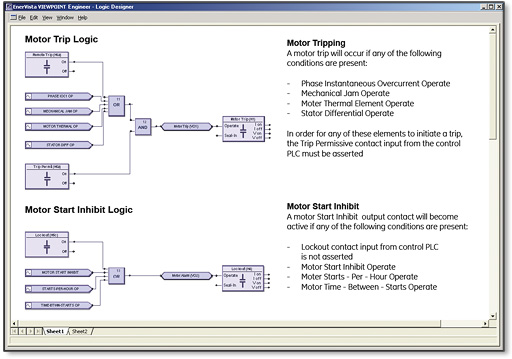

The M60 incorporates advanced automation features including powerful FlexLogic™ programmable logic, communication, and SCADA capabilities that far surpass what is found in the average motor protection relay. The M60 integrates seamlessly with other UR relays for complete system protection, including adjacent motors, feeders and other balance of plant protection.

FlexLogic™ allows for the customization of the M60 to operate and control the breakers and other auxiliary devices needed to fit most motor protection schemes and applications.

Key Features

Advanced Communications

The M60 provides advanced communications technologies for remote data and engineering access, making it the easiest and most flexible Motor protection relay to use and integrate into new and existing infrastructures. Direct support for fiber optic Ethernet provides high-bandwidth communications allowing for low-latency controls and high-speed file transfers of relay fault and event record information. The available three independent and redundant Ethernet options provide the means to create fault tolerant communication architectures in an easy, cost-effective manner.

The M60 supports the most popular industry standard protocols enabling easy, direct integration into DCS and SCADA systems.

Interoperability with Enbedded IEC 61850

Use the M60 with integrated IEC 61850 to lower costs associated with motor protection, control and automation. GE’s leadership in IEC 61850 comes from thousands of installed devices and follows on years of development experience with UCA 2.0.

The M60’s IEC 61850 Process Bus module is designed to interface with the Multilin HardFiber System, allowing bi-directional IEC 61850 fiber optic communications. The HardFiber System is designed to integrate seamlessly with existing Universal Relay applications, including protection functions, FlexLogic, metering and communications. Learn more

Cyber Security - CyberSentry™ UR (FW v7.4xx)

CyberSentry enables UR devices to deliver full cyber security features that help customers to comply with NERC CIP and NITIR 7628 cyber security requirements through supporting the following core features:

Secure FW upgrade

UR FW files v7.9 and up now include a hash code that allows for authentication prior to being used for upgrading UR devices.

Password Complexity

Supporting up to 20 alpha- numeric or special characters, UR passwords exceed NERC CIP requirements for password complexity. Individual passwords per role are available.

AAA Server Support (Radius)

Enables integration with centrally managed authentication and accounting of all user activities and uses modern industry best practices and standards that meet and exceed NERC CIP requirements for authentication and password management.

Role Based Access Control (RBAC)

Efficiently administrate users and roles within UR devices. The new and advanced access functions allow users to configure up to five roles for up to eight configurable users with independent passwords. The standard “Remote Authentication Dial In User Service” (Radius) is used for authentication.

Event Recorder (Syslog for SEM)

Capture all cyber security related events within a SOE element (login, logout, invalid password attempts, remote/local access, user in session, settings change, FW update, etc), and then serve and classify data by security level using standard Syslog data format. This enables UR devices integration with established SEM (Security Event Management) systems.

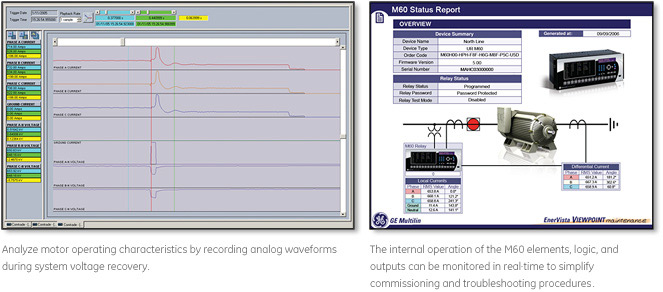

EnerVista™ Software

The EnerVista™ suite is an industry-leading set of software programs that simplifies every aspect of using the M60 relay. The EnerVista™ suite provides all the tools to monitor the status of the protected asset, maintain the relay, and integrate information measured by the M60 into DCS or SCADA monitoring systems. Convenient COMTRADE and Sequence of Events viewers are an integral part of the UR setup software included with every UR relay, to carry out postmortem event analysis and ensure proper protection system operation. Learn More